| Sign In | Join Free | My himfr.com |

|

- Home

-

Products

- Phase Changing Materials(38)

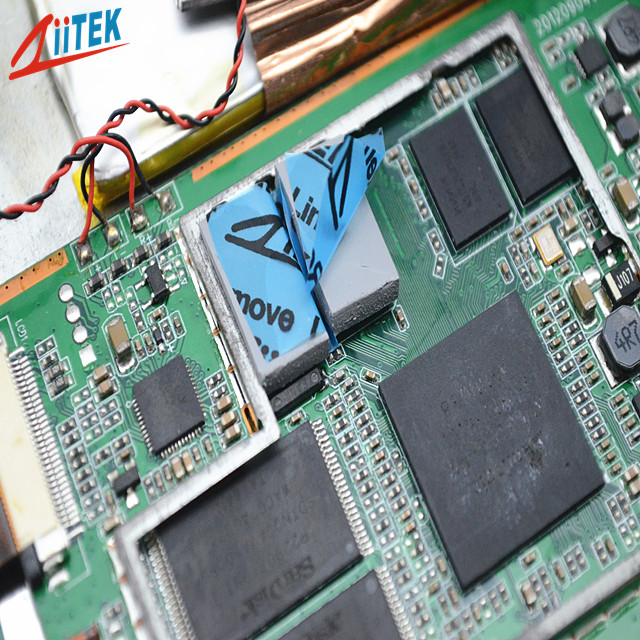

- Thermal Conductive Pad(155)

- Thermal Gap Filler(189)

- Thermal Conductive Grease(27)

- Thermal Insulation Materials(46)

- Thermal Graphite Sheet(53)

- Thermal Adhesive Tape(47)

- Thermal Conductive Glue(15)

- Thermal Conductive Adhesive(13)

- Thermal Conductive Plastic(23)

- Sponge Foam Material(13)

- PET Double Sided Tape(11)

- Thermal Gap Pad(406)

- Thermal Conductive Gel(22)

- Silicone Foam Gasket(11)

- Silicone Free Gap Filler Pad(13)

- Shielding Absorbing Materials(19)

- Thermal Conductivity Sharp Metal(2)

- About Us

- Quality Control

- Contact Us

- Get Quotations