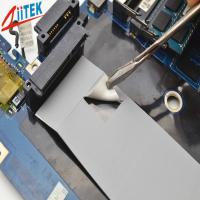

Ceramic Filled Silicone Rubber Thermal Insulation Materials For

Heatsink Cooling TIS806

The TIS806 products are the high-efficiency insulation ones with thermal

conduction properties. The supplement of the insulation base film

made by silica gel into the heat-conduction material creates a

great effect on both the insulation and heat conduction.

The selection of thermal conductive interface materials should

consider electrical insulation, chemical stability, corrosion to

the material, environmental impact and flammability and media cost.

TIS800, the thermal conductive insulation sheet launched by Zhake,

has the performance to meet the heat dissipation requirements of

frequency converter, the substrate, the performance meets the

requirements, the installation is convenient, the work efficiency

is improved, and the labor cost is greatly reduced.

TIS800

Series Datasheet-(E)-REV01.pdf

Features

> Highly compliant surface characteristic with high thermal

conductivity

> High thermal conductive and High dielectric strength

> Low thermal resistance with high voltage isolation

> Resistant to tears and punctures

Applications

> Power conversion equipment

> Power semiconductors:To packages, MOSFETs & IGBTs

> Audio and Video components

> Automotive control units

> Motor controllers

> General high pressure interface

| Typical Properties of TIS806 Series |

| Product Name | TISTM806 | TISTM808 | TISTM810 | TISTM812 | TISTM818 | Test Method |

| Color | Gray | Gray | Gray | Gray | Gray | Visual |

Construction &

Compostion | Ceramic filled silicone rubber | *** |

| Composite Thickness | 0.006"/0.152 mm | 0.008"/0.203mm | 0.010"/0.254mm | 0.012"/0.304mm | 0.018"/0.457mm | ASTM D751 |

| Specific Gravity | 2.2 g/cc | ASTM D297 |

| Heat Capacity | 1 l/g-K | ASTM C351 |

| Hardness | 50 Shore A | ASTM 2240 |

| Tensile Strength | 450 psi | >600 psi | >600 psi | >600 psi | >600 psi | ASTM D412 |

| Continuos Use Temp | (-58 to 356℉) / (-50 to 180℃) | *** |

| Electrical | |

| Dielectric Breakdown Voltage | >1500 VAC | >3500 VAC | >5000 VAC | >5000 VAC | >5000 VAC | ASTM D149 |

| Dielectric Constant | 5.5 MHz | ASTM D150 |

Volume Resistivity | 5.0X10" Ohm-meter | ASTM D257 |

| Fire rating | 94 V0 | equivalent UL |

| Thermal | |

| Thermal conductivity | 1.6 W/m-K | ASTM D5470 |

Thermal Impedance @50psi | 0.21℃-in²/W | 0.35℃-in²/W | 0.82℃-in²/W | 1.23℃-in²/W | 1.83℃-in²/W | ASTM D5471 |

Standard Thicknesses:

0.005"(0.127mm) 0.006"(0.152mm) 0.008"(0.203mm) 0.009"(0.228mm)

0.010"(0.254mm) 0.012"(0.304mm) 0.018"(0.457mm)

Consult the factory alternate thickness.

Standard Sizes:

16" x 18"(406mm x 457mm) 16" x 200'(406mm x 60.9M)

Individual die cut shapes can be supplied.

Packaging Details & Lead time

The packaging of thermal pad

1.with PET film or foam-for protection

2. use Paper Card To Separate Each Layer

3. export carton inside and outside

4. meet with customers' requirement-customized

Lead Time :Quantity(Pieces):5000

Est. Time(days): To be negotiated

Ziitek Culture

Quality :

Do it right the first time, total quality control

Effectiveness:

Work precisely and thoroughly for effectiveness

Service:

Quick response, On time delivery and Excellent service

Team work:

Complete teamwork, including sales team, Marketing team,

engineering team, R&D team, Manufacturing team, logistics team.

All is for supporting and servicing a satisfy service for

customers.